John Tullett is a former art teacher with a Bachelor of Fine Arts. He uses a meticulous, multi-step bronze casting technique to create his work.

John Tullett is a former art teacher with a Bachelor of Fine Arts. He uses a meticulous, multi-step bronze casting technique to create his work.

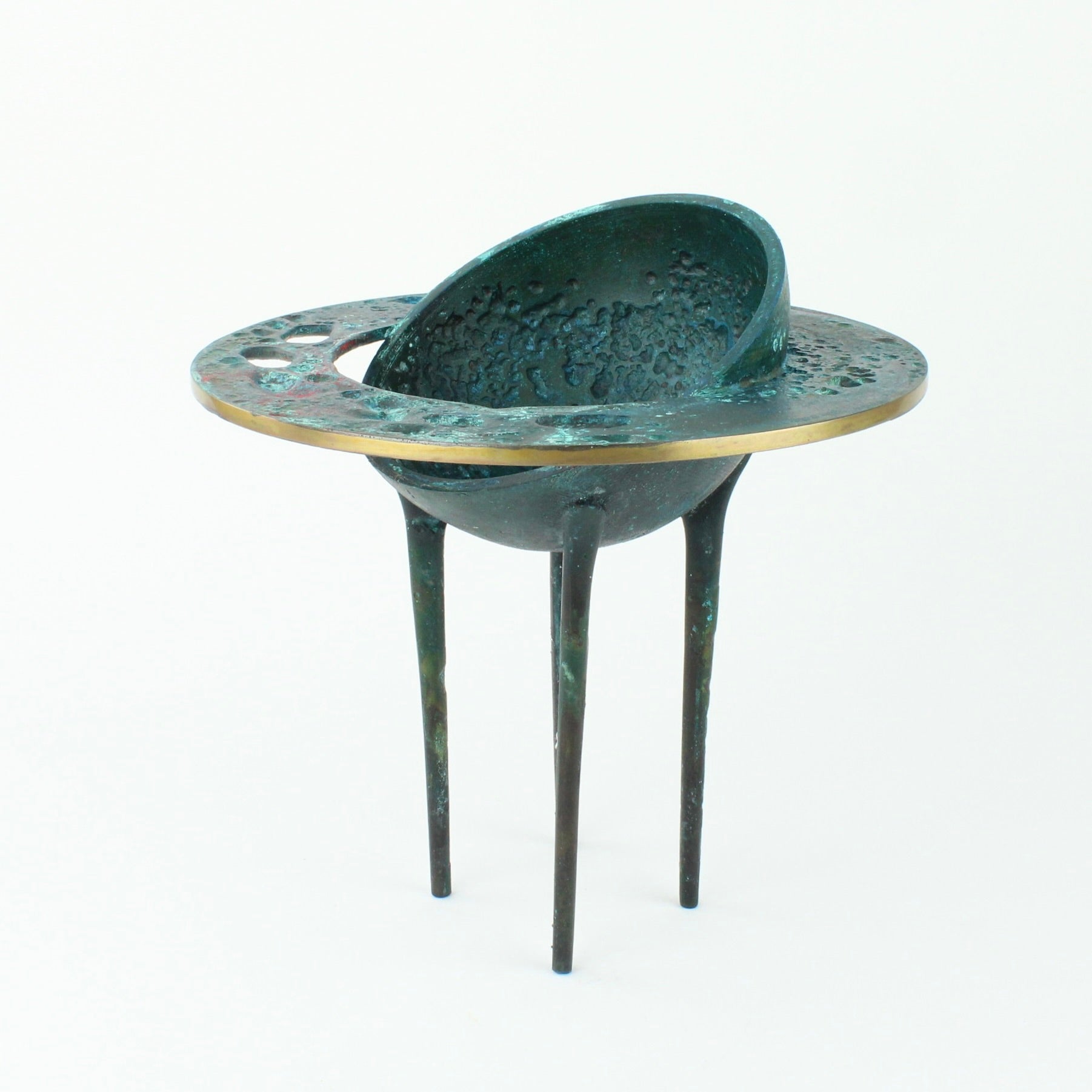

Each piece begins as a wax model, which is coated in multiple layers of ceramic shell. Once the wax is melted out and the mould is fire-cured, molten bronze, heated to 1150°C in a gas-fired furnace, is poured into the mould. As the bronze cools, the ceramic shell breaks away.

The casting is then carefully fettled using files and sandpaper, and chased to refine surface textures and correct any imperfections. After selective polishing and the application of copper-reactive patinas for colour, a protective wax coating is applied.

John typically works in batches of ten to twelve pieces, with each batch taking approximately sixty hours to complete.

John Tullett is a former art teacher with a Bachelor of Fine Arts. He uses a meticulous, multi-step bronze casting technique to create his work.

Each piece begins as a wax model, which is coated in multiple layers of ceramic shell. Once the wax is melted out and the mould is fire-cured, molten bronze, heated to 1150°C in a gas-fired furnace, is poured into the mould. As the bronze cools, the ceramic shell breaks away.

The casting is then carefully fettled using files and sandpaper, and chased to refine surface textures and correct any imperfections. After selective polishing and the application of copper-reactive patinas for colour, a protective wax coating is applied.

John typically works in batches of ten to twelve pieces, with each batch taking approximately sixty hours to complete.

Bronze bowl VI

$700.00

Bronze bowl V

$800.00

Bronze bowl IV

$800.00

Wing Bowl

$800.00

Four Legged Bowl

$700.00

Meteor Bowl

$800.00

Bronze bowl I

$800.00

Bronze bowl II

$700.00